Manufacturing-X

A data ecosystem and initiative

Manufacturing-X is a data ecosystem and industry, academia and policy initiative that aims to optimize and modernize industrial supply chains and production processes.

A new generation of manufacturing technology

The Manufacturing-X concept represents a new generation of manufacturing technology, incorporating Industry 4.0 approaches and merging technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), robotics, and data analytics. The objective of the Manufacturing-X concept is to ensure more efficient, flexible, and cost-effective production processes while establishing a highly adaptive manufacturing environment capable of responding to individual customer demands and real-time market needs.

Participating companies and industries

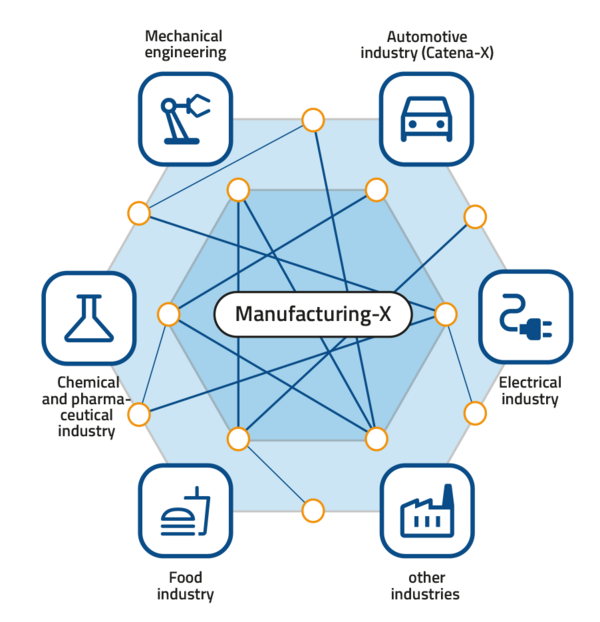

The initiative involves numerous industrial conglomerates such as Siemens, Bosch, Trumpf, SAP, and Deutsche Telekom, as well as medium-sized companies, startups, and associations like ZVEI, VDMA, and Bitkom. The concept isn't confined to a single industry but rather encompasses sector-specific adaptations in areas such as mechanical engineering and electronics, chemicals and pharmaceuticals, as well as food and beverage production. The approach has reached an advanced stage, particularly within the automotive industry through the Catena-X project – thus, Catena-X can be seen as a blueprint for other sectors.

In general terms, Manufacturing-X is an open-source data space, which means an ecosystem in which data is exchanged using predefined rules and standards. So, there are no closed systems, unlike large cloud services. One key aspect is that all the relevant components and stakeholders in the production chain are networked. This includes machines, people, workpieces, and networked devices managed in a dynamic and interactive way. The data points this produces can then be leveraged to optimize production, predict maintenance requirements, and adapt systems to changing requirements.

The applications and business models that can be derived from this include networked just-in-time production, the rental of machines, and quantifying production facility processes on a minute-by-minute or unit basis. It isn’t yet fully clear which data-based services this will give rise to, or how the businesses involved will be able to profit from them. But the aim of exchanging data and standardizing is to generate added value for the German industry.

Stay up to Date

Subscribe to the AUVESY-MDT newsletter and get exclusive insights and updates from the world of automation.

Operational Technology (OT) Protection Requirements

But at the same time, the progressive networking of production facilities in industrial manufacturing also means that operational technology (OT) needs greater protection. Businesses, therefore, need to look to software solutions that help them back up their systems and increase their cybersecurity. This can reduce attacks and security risks and allow production capability to be restored quickly in the event of damage.

Potential for industrial production

All in all, Manufacturing-X has the potential to fundamentally change industrial production and the way in which products are developed, manufactured, and delivered. It represents a special challenge, as well as an opportunity for industrial companies that are ready to chart a new course toward an agile, networked, customer-centric production landscape. It will allow industrial businesses and system operators to increase the efficiency of their production processes, shorten time-to-market, and improve product quality while reducing production costs.